In the world of salt production, having a high-quality salt processing plant is crucial for efficiency, purity, and sustainability. A salt processing plant is designed to optimize the extraction, refining, and packaging of salt. It plays a vital role in numerous industries, from food and pharmaceuticals to industrial applications. Our salt processing plants are engineered to provide top-notch results, ensuring maximum yield and product quality. This article will take a deep dive into how salt processing plants work, their importance, and why investing in the right plant can make a huge difference for businesses.

What is a Salt Processing Plant?

A salt processing plant is a facility where raw salt is refined, processed, and packaged for various uses. Whether extracted from seawater or rock salt deposits, raw salt undergoes multiple stages of purification and crystallization to meet quality standards. From washing and grading to dehydration, these plants make sure that the salt reaches the highest level of purity required for various applications. The need for an efficient salt processing plant has grown significantly as the global demand for refined salt continues to rise.

Why Choose an Advanced Salt Processing Plant?

For businesses that rely heavily on salt, an advanced salt processing plant can be a game-changer. These plants are equipped with state-of-the-art technology, allowing for efficient processing and high-quality output. An optimized salt processing plant minimizes waste, lowers energy consumption, and helps companies meet sustainability goals. With advanced purification techniques, they also ensure that the salt is free from impurities, making it suitable for sensitive applications such as food and medical use.

Fact: According to recent statistics, global salt production reached 270 million metric tons in 2023, with demand projected to grow annually, especially in food and industrial sectors.

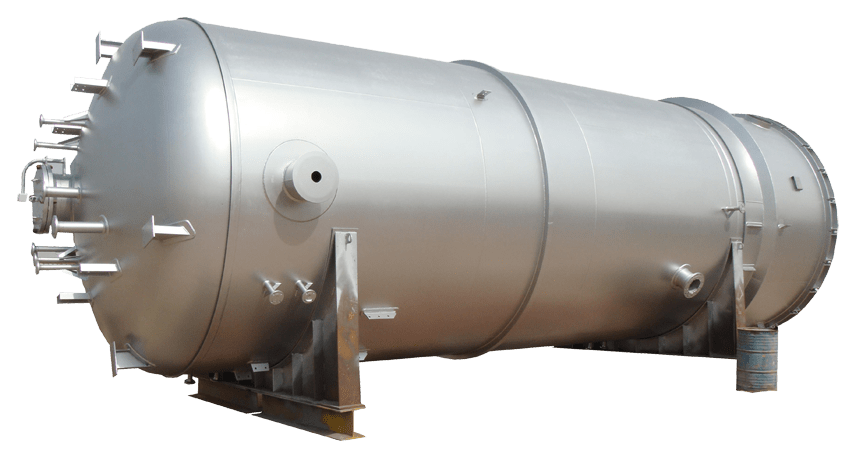

Key Components of a Salt Processing Plant

Understanding the key components of a salt processing plant will provide insight into how these facilities contribute to optimal salt production.

1. Raw Material Intake and Pre-Treatment

The process starts with the intake of raw salt. The salt is then pre-treated to remove impurities like dust, stones, and other foreign materials. This is essential to ensure that the end product is of the highest quality.

2. Crushing and Milling Units

Crushing and milling are essential to break down the salt to the desired granule size. The salt is ground to meet specific standards, which can vary based on its intended use.

3. Washing and Grading

The washed salt undergoes grading to separate it based on particle size and quality. This step ensures that the salt meets customer specifications, particularly for those in the food and pharmaceutical industries.

4. Drying and Dehydration

Drying and dehydration are crucial for reducing the moisture content of the salt, making it stable for storage and transportation. A well-designed salt processing plant incorporates efficient drying techniques, lowering energy consumption while ensuring product quality.

5. Packaging and Distribution

Once processed, the salt is packaged and prepared for distribution. Modern plants use automated systems for packaging, improving speed and efficiency. Packaging options can range from bulk containers to smaller, retail-friendly sizes.

Benefits of Investing in a Modern Salt Processing Plant

A modern salt processing plant can yield multiple benefits for businesses, from higher output to better sustainability.

Improved Production Efficiency

Advanced salt processing plants are designed to enhance efficiency, allowing companies to produce larger quantities in less time.

High-Quality End Product

With strict control over each processing stage, these plants ensure that the final product is pure and meets specific quality standards.

Lower Operational Costs

Modern plants are optimized for energy efficiency, reducing the overall cost of production.

Environmental Sustainability

With features like water recycling and energy-efficient operations, these plants can help companies reduce their carbon footprint, aligning with global sustainability goals.

Applications of Salt Processed in a Salt Processing Plant

Salt processed in a salt processing plant is used across various sectors, including:

- Food Industry – Purified salt is essential for food production and preservation.

- Pharmaceutical Industry – Salt used in medicines and other healthcare products requires a high level of purity.

- Water Treatment – Processed salt is crucial for water softening and purification systems.

- Industrial Uses – Salt is used in various chemical processes and for de-icing roads.

Choosing the Right Salt Processing Plant Manufacturer

Selecting a reliable manufacturer is key to ensuring that a salt processing plant meets your business needs. Look for companies with a proven track record in delivering high-quality, sustainable salt processing solutions. The right plant manufacturer will understand your specific requirements and customize the plant to enhance productivity and quality.

A Look at the Future: Innovations in Salt Processing Plants

The future of salt processing plants lies in automation, sustainability, and efficiency. With advancements in artificial intelligence and automation, plants can now monitor each stage of production in real-time, reducing human error and increasing overall output. As environmental regulations become stricter, manufacturers are also focusing on sustainable practices like recycling water and reducing emissions. Companies investing in modern, eco-friendly salt processing plants stand to gain a competitive edge in the market.

Conclusion

To meet the growing demand for salt in various industries, businesses must invest in high-quality salt processing plants that provide efficiency, purity, and reliability. A well-designed salt processing plant is not only a financial investment but also a step towards sustainability and operational efficiency. As we move towards an increasingly regulated and quality-focused market, choosing the right salt processing plant can make a significant difference.

In conclusion, with advanced technology and a focus on sustainability, salt processing plants are becoming indispensable assets for companies that depend on high-quality salt for their operations. If you’re considering an upgrade or investment in salt processing, now is the perfect time to look into the options available to ensure that your plant meets both current needs and future demands.

Buraq Engineering is a global leader in designing and delivering high-quality salt processing plants that meet diverse industry needs. Known for innovation, efficiency, and sustainability, Buraq Engineering ensures each plant is built with advanced technology to provide optimal salt purity, reliability, and cost-effective operations. With a strong commitment to quality and customer satisfaction, Buraq Engineering has earned a reputation worldwide for providing top-notch salt processing solutions that support industries ranging from food and pharmaceuticals to industrial applications.